Image Measurement Software

Quartz PCI provides easy-to-use tools for quick, precise measurements in images of lengths, angles, areas, perimeters and more.

PCI also includes comprehensive Processing Tools, such as fine rotation, tilt correction and contrast and brightness adjustments, to prepare your images for measurement.

Calibration

PCI reads calibration information directly from files saved by most electron microscope manufacturers including FEI, Hitachi, JEOL, Phenom, Tescan and Zeiss. It will also read calibration information from Gatan DM3 and DM4 files. This means that images are ready to measure immediately upon loading with no separate calibration step.

For images that require manual calibration, PCI offers two methods. In the first method, images can be calibrated by measuring a known length in the image (this could be a feature of the image or a micron marker embedded in the image). In the second method, it is possible to predefine the calibration of your instrument by entering the length of a measured dimension at a particular magnification. You can then calibrate subsequent images simply by entering the magnification.

Images can be calibrated and measured in units of nanometers, microns, millimeters, centimeters, meters, Angstroms, mils, inches and feet and PCI will perform correct conversions between measurement systems. Uncalibrated images can be measured in pixels.

If you wish, a scale bar (micron marker) can be added to your images once they are calibrated.

Manual Measurement Tools

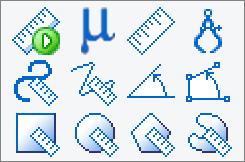

PCI includes a simple point-to-point distance measuring tool, as well as a caliper tool for measuring distances where the endpoints are offset. In addition to the distance between the measurement points, the system will compute X and Y projections and the angle of the measured line segment.

Tools are provided for measuring the lengths and other properties of freehand curves and polylines.

And, tools are provided for characterizing two dimensional shapes, including rectangles, circles, ellipses, polygons and freehand shapes. For these shapes, the system will compute Area, Perimeter, Length, Breadth and Angle.

Finally, both three point and four point angle measurement tools are provided. In addition to measuring the angle, the system also records the lengths of the arms of the angle.

For each measurement, you can control how it is displayed on the image. You can specify whether to show a label for the measurement, the numerical values associated with the measurement and the number of significant digits to show. You can also control graphical elements, including color and line thickness, and whether to display arrowheads, extension lines and so on.

Measurement and Annotation Overlay Layer

All of the measurements and annotations that you make on an image are contained in a separate overlay layer. This means that they can be moved and adjusted without affecting the underlying image.

At the appropriate time, you can choose to “burn” your annotations into the image to make them permanent.

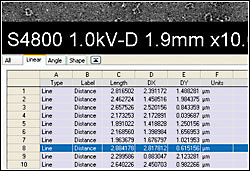

Measurement Grid / Measurement Export

As you make measurements, the details of each measurement are added to a spreadsheet grid at the bottom of the image window. The contents of this grid can be easily copied via the clipboard into other software, such as Excel, and can be exported as a CSV file suitable for importation into other software.

The measurement grid can also be placed in PCI Reports allowing you to present your measurement data and images together in an effective manner.

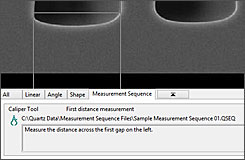

Measurement Sequence

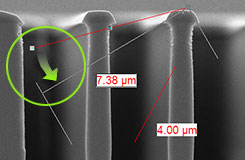

Quality control and semiconductor process development applications often require the same set of measurements to be repeated on multiple images. PCI’s Measurement Sequence functions can guide an analyst through a series of pre-defined, manual measurements, automatically selecting the appropriate tool and settings for each measurement.

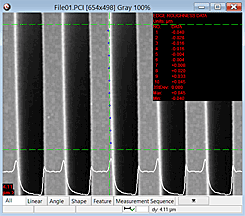

Semiconductor Metrology

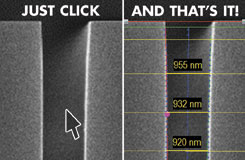

PCI includes tools for measuring line widths, pitches and edge roughnesses in images of semiconductor samples. To use these tools, you place cursors near the appropriate edges and the system will “snap” these cursors to the edges.

Automated Measurement

Quartz PCI-AM, our optional automated measurement module lets you make automated measurements of semiconductor features, including trenches and pillars, lines and spaces and two-dimensional shapes, such as contact holes, vias and conductor cross sections.

With the PCI-AM module, the manual PCI measurements functions discussed above can be set to snap to edges in the image.